Sewing Machine Needle A to Z

Md. Masudur Rahman

Department of Textile Engineering

4th Batch

National Institute of Textile Engineering and Research

(NITER)

masudbdasia@gmail.com

masudbdasia@gmail.com

(To view as slide or download click here )

Google Drive link

v# Introduction

|

The

central feature of any sewing machine is the needle or needles. Very many

needle types (systems) have been developed over time to ensure each sewing

machine that uses them performs at its best.

Needle

systems may be introduced for a number of reasons such as the introduction of

new or specialized fabrics, new sewing machinery or even increases in machine

speed.

#The basic functions of a needle

- To create a passage in the material for the thread to pass through.

- To carry the needle thread through the material and form a loop which can be picked up by the hook or looper mechanism.

- To pass the needle thread through the loop formed by the looper mechanism on machines other than lockstitch

# Needle Parts

The starting part of bottom edge of needle. Helps for easily attaching of needle with the needle bar or clamp

The intermediate section between the shank and the blade of needle. When the

needle penetrate through the fabric to reach its lower position, then the

shoulder also penetrates through the fabric. As a result it reduces the

friction between needle & fabrics by producing a wider hole on fabric.The bottom thicker part of the needle which is tied in the needle clamp or the needle set screw. It may be cylindrical or flat in size. It supports the needle as a whole by providing additional strength |

|

| Needle parts |

6. Short groove

It is formed on the other side of long groove, towards the shuttle, hook, or

looper and it assists in throwing the loop of needle thread

7.

Eye

The eye of the needle is present in the bottom end of the blade. Needle thread

allowed through this eye is taken to the bottom area. It helps to create loop

8. Scarf (Clearance)

It is a curved slot, a clearance cut in the needle blade just above the eye to

permit a closer setting of the shuttle, hook, or looper to the needle. As a

result, it is easy to catch the needle loop by the looper hook.

9.

Point

It is the part from needle eye to the tip. The point of the needle is shaped to

provide the most suitable penetration of the material being sewn according to

its nature and the desired stitch effect

10.

Tip

The ending edge pf needle is called tip. It helps to penetrate the needle into the fabric and create hole during sewing.

The ending edge pf needle is called tip. It helps to penetrate the needle into the fabric and create hole during sewing.

#Selection of

Needle

There

are various sizes of needle and needle should be select according to types of

fabrics and sewing thread. The size of needle is expressed directly by a number

on the manufactures but metric size is the simplest and widely used. Shortly it

is denoted by Nm. Needle size is expressed by measuring diameter of the middle

of the needle blade. For example, the diameter in the middle of a needle blade

is 0.9 mm, and then the needle size would be 90 Nm. If the diameter of the

middle of a needle blade is 1.2 mm then the needle size would be 120 Nm. Generally

for finer fabric, sewing thread and needle should be finer.

# Effects of Wrong Needle Selection in

Apparel Industry

- When the needle is finer than sewing thread

- When the thread is finer than needle

- When the needle is coarser than required fabric

- When the needle is finer than required fabric

|

1. Effects when the needle is finer than sewing thread:

- When the sewing needle is finer than sewing thread cannot move easily through the needle eye.

- The thread will not take position accurately at the needle long groove.

- More heat will generate on the needle for higher friction

- The ultimate results the thread breakage and garments production loss.

2. Effects when the thread is finer than needle:

• When the thread is finer than sewing needle then it may produce

slipped stitch as the needle can’t create perfect size of loop.

3. Effects when the needle is coarser than required fabric:

• The fabric will be looked odd due to the larger hole.

• Seam puckering may produce on woven fabric.

• Seam puckering may produce on woven fabric.

4. Effects when the needle is finer than required fabric:

•During sewing needle will deflect and become curve with the action of the throat plate.

•This type of curve needle will produce slip stitch as the looper may not catch the loop needle thread.

#Needle Identification

A sewing machine needle is identified with three parameters and they are:

•System

•Point

•Size

•System

•Point

•Size

1. System

A needle system defines the dimensions of a needle to suit the machine type. Depending on the machine and its stitch type, the needle is designed with variations in length of blade, shank thickness, type of eye etc. It is advisable to check with the machine manufacturer for suitability of needle system to machine.

2. Point

A needle point is classified broadly into two types

a) Cutting Point or Leather Pont

b) Cloth Points or Round Set

a) Cutting Point or Leather Pont

b) Cloth Points or Round Set

1. Cutting Point Needles

Cutting

point needles have sharp tips like blades. These tips are available

with a wide variety of cross-sectional shapes such as lens, rounded,

triangular and square. They can be used while sewing dense, non-fabric

based material like plastic, leather. Because, there is no gap in these

types of materials. They pierce the material more readily than the round

point types thereby generating less needle heat. There are a large

number of cutting points of which around 11 are in regular use.

But mainly cutting point is divided into three types:

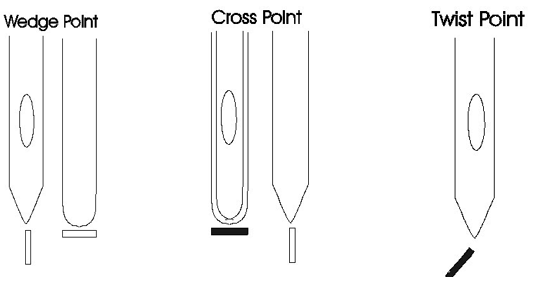

a) Wedge Point

It produces most durable seam on leather. It resists great stress, the incision lie at right angle to the seam direction and high stitch density can be achieved.

b) Cross Point

Here strength is considerably weakened. The material is likely to tear if stress is at the right angle. The incisions lie parallel to the direction of the seam.

c) Twist Point

The strength is intermediate and the incisions like 45 deg. to the direction of the seam.

But mainly cutting point is divided into three types:

a) Wedge Point

It produces most durable seam on leather. It resists great stress, the incision lie at right angle to the seam direction and high stitch density can be achieved.

b) Cross Point

Here strength is considerably weakened. The material is likely to tear if stress is at the right angle. The incisions lie parallel to the direction of the seam.

c) Twist Point

The strength is intermediate and the incisions like 45 deg. to the direction of the seam.

Cutting

Points Overview

Cutting

points spear

Cutting

point wedges

b). Cloth Points or Round Set Needles

These are used for sewing textile materials like fabrics. The point of needle should be round in cross section. But tip depends on fabric like knitted or woven. There are believed to be around twenty different round points available out of these six are in common use. These are mainly divided into two types.a) Ball Point Needle

b) Set point Needle

a) Ball Point Needle

The thread in the knitted fabrics are bounded in loop from. If any thread of loop is drawn-off due to any reason, then the hole structure of the fabric starts to be opened out. For this reason the point of needle should be as to prevent the opening of structure of knitted fabric. As a result ball point needles are used for sewing knitted fabric. Generally three types of ball point needle are used. I. Light Ball Point (SES)

I. Light Ball Point (SES) This

point is used for sewing lightweight knitted fabric. It is sometimes

used for fine denim and light, densely woven material to avoid damaging

the material.

This

point is used for sewing lightweight knitted fabric. It is sometimes

used for fine denim and light, densely woven material to avoid damaging

the material.II. Medium Ball Point (SUK)

This point is used for sewing medium weight knitted fabric. It is also used for medium to coarse denims, particularly sand-washed and stonewashed grades.

III. Heavy Ball Point (SKF)

This point is used for coarse knitwear and for sewing dense woven elastic (it won’t push the elastic yarn through).

IV. Special ball point (SKL)

Used for medium to course elastic materials with covered elastomeric threads and very coarse knitwear.

b) Set Point Needles

Generally set pointed needles are used for sewing woven fabrics. Mainly set point needle are three.1. Slim Set Point also referred to as acute round point (SPI)

This point is used for dense woven fabrics as it causes less damage, helps set a straighter stitch and minimizes seam pucker. Commonly used for micro fibre and densely woven fabrics, coated materials, top stitching of collars and cuffs in shirts.2. Medium Set Point Needle (R):

Most of the fabric can be sewn by this type of needle and knitted fabric can also be sewn.3. Heavy Set Point Needle:

Generally heavy set point needle is used for sewing button. There is a less possibility of button deflection due to use of heavy point needle# Needle Size / Thickness

The size of a needle is generally represented in one of two ways (although there are others). The European metric sizing system for sewing machine needles is numbered from 60 to 110. The American sizing system is numbered from 8 to 18.

By metric number or European number (Nm) represents the diameter of the needle blade in hundredths of a millimeter measured just above the scarf but not at any reinforced part of the blade.

For example, a Nm 110 needle is 1.1 millimeter in diameter, while a Nm 50 needle is half a millimeter in diameter.

For both sizing systems, the lower the number the finer the needle and the higher the number the larger the needle.

The thickness of the blade on the right is 1.1mm wide which is shown in Nm as 110.

The alternative standard needle sizing method is the Singer/Asia numbering system sometimes referred to as the American system that uses a number that represents a size.

|

| Needle Size according to fabric weight |

|

| Needle point and size according to fabric |

|

| Needle Package |

TO downolad file click here

3 comments

Click here for commentsThis blog is really helpful regarding all educational knowledge I earned. It covered a great area of subject which can assist a lot of needy people. Everything mentioned here is clear and very useful. Brother se600

ReplySomewhere the content of the blog surrounded by little arguments. Yes it is healthy for readers. They can include this kind of language in their writing skill as well as while group discussion in college. Best sewing machine for beginners

ReplyWow, I would have in mind when i need to set needles first

Replysewing machine parts manufacturer

ConversionConversion EmoticonEmoticon